Dry ice blasting, also known as CO2 blasting, is a cutting-edge cleaning process that uses solid carbon dioxide pellets (dry ice) to clean surfaces. Unlike other cleaning methods, dry ice blasting does not use water, chemicals, or abrasive materials. Instead, the dry ice pellets are propelled at high speeds onto the surface that needs cleaning, sublimating upon impact and lifting away contaminants

- Acceleration: Dry ice pellets are fed into a blasting machine where they’re accelerated to high velocities

- Impact: These high-speed pellets then impact the surface, removing the contaminants

- Sublimation: Upon hitting the surface, the dry ice pellets instantly sublimate (turn from solid to gas), expanding rapidly.

- Cleaning: This rapid expansion and sublimation causes contaminants to break off from the surface, resulting in a clean, contaminant-free area.

- Eco-Friendly: With no chemicals and no secondary waste, dry ice blasting is environmentally friendly and reduces the need for waste disposal.

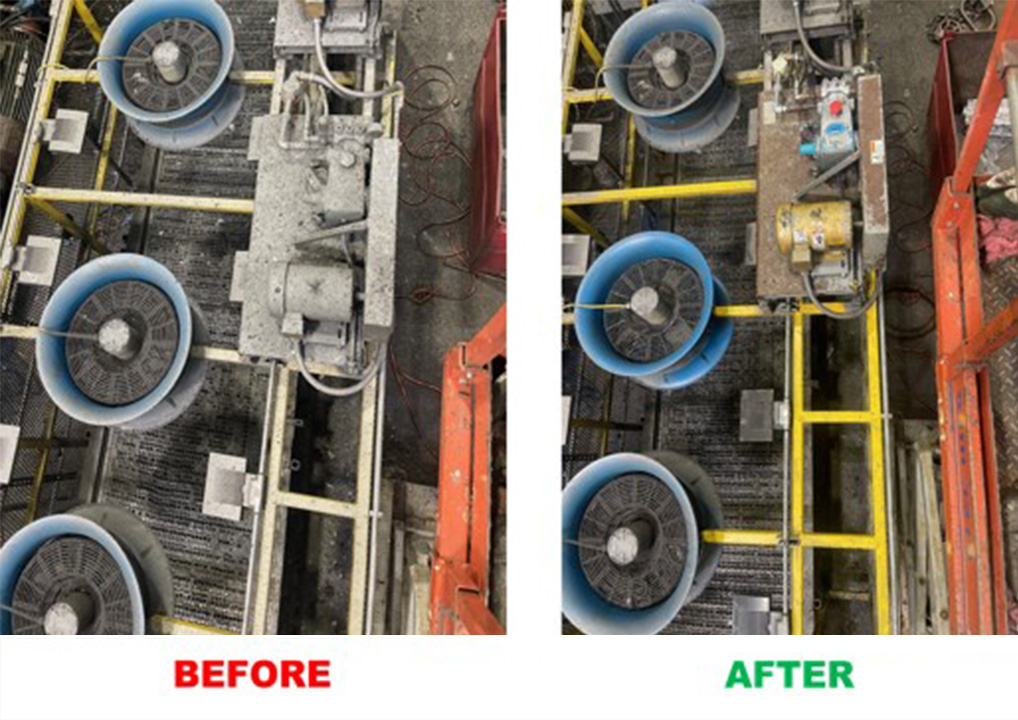

- No Downtime: Equipment and machinery can often be cleaned in place without disassembly, meaning less downtime for industries and businesses

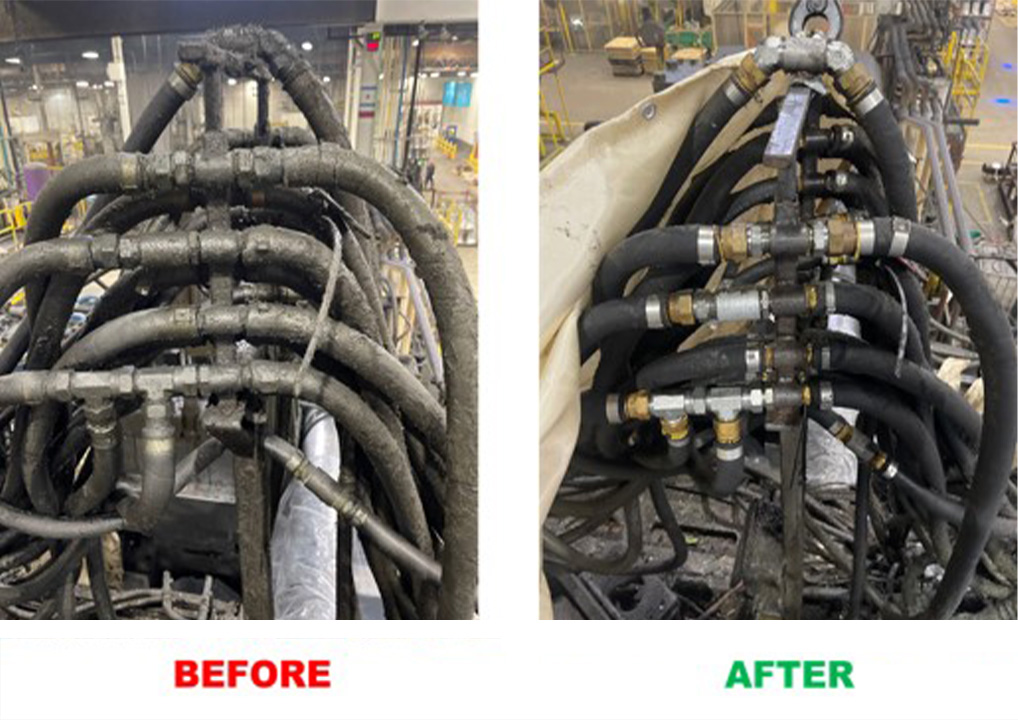

- No Abrasion: As there are no hard, abrasive materials used, there is minimal wear on the target surface.

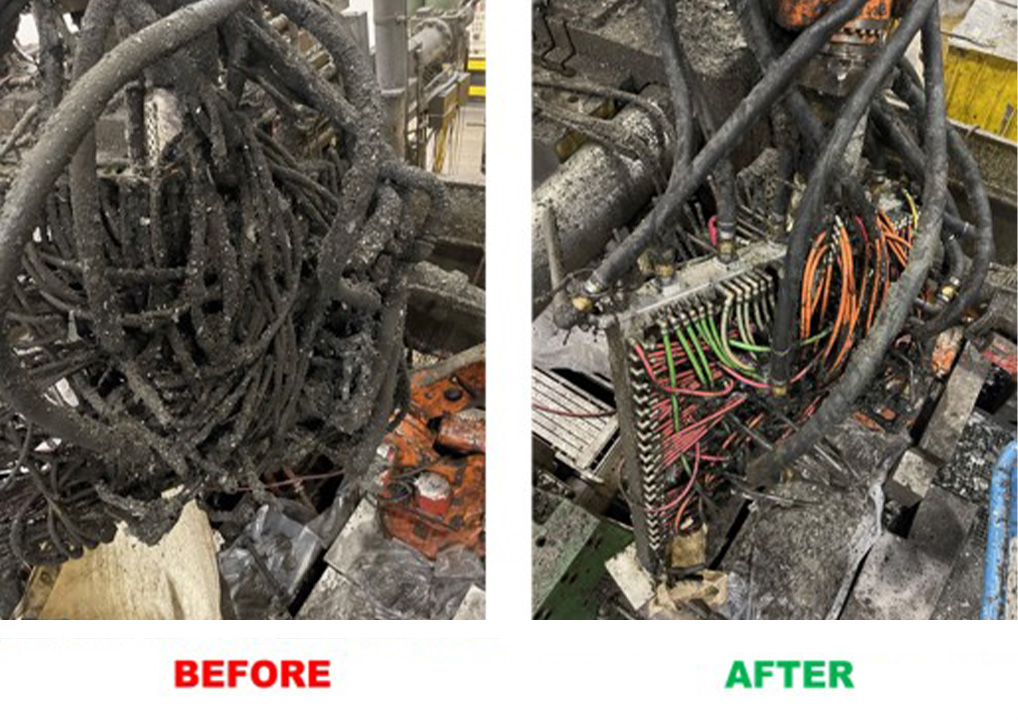

- Safe for Electricals: Dry ice is non-conductive, making it safe for use on electrical components.

- No Residue: Since dry ice sublimates into CO2 gas, there’s no residue left behind after the cleaning process

- Decreased Labor Costs: Faster cleaning times and the ability to clean machinery in place can lead to reduced labor costs.

- Versatile: Effective for a wide range of industries, from automotive to food processing and from graffiti removal to fire restoration.

Whether you’re looking to restore old machinery, maintain critical equipment, or achieve the highest levels of sanitation, our dry ice blasting services offer a superior cleaning solution for all your needs. Contact us today to find out how we can help elevate your cleaning processes.